Quick Closing Hydraulic Butterfly Valve

The quick-closing hydraulic-controlled butterfly valve designed by Dazhong Valve Group is mainly installed in the steam extraction pipeline of the steam turbine and the TRT intake pipeline of the blast furnace gas pressure power generation device. It consists of four major parts: hydraulic system and electrical control system. The main valve is a triple eccentric metal-sealed butterfly valve, and the electrical control system is divided into ordinary relay type and PLC intelligent control type according to the main logic element category. It also has a 15% stroke "swimming" function in the fully open state to avoid valve jamming.

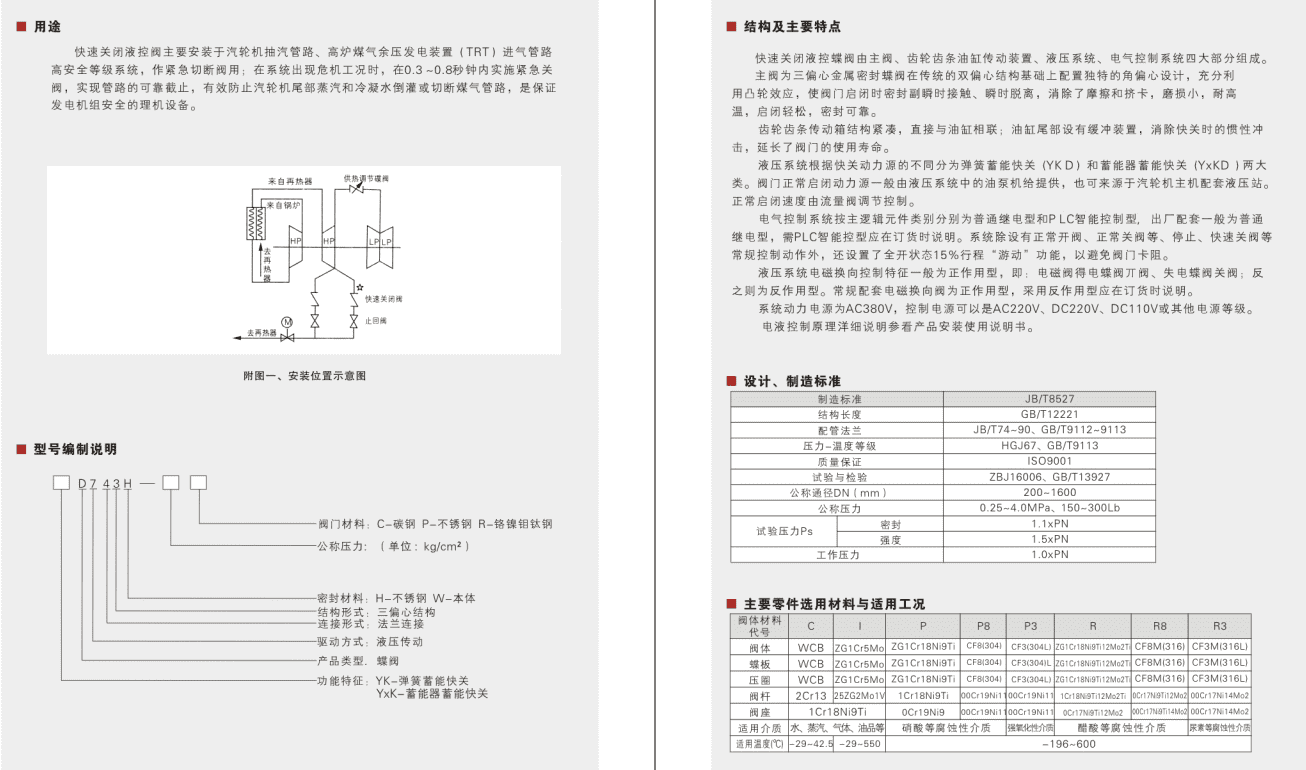

The quick-closing hydraulic butterfly valve is mainly installed in the high-safety level system of the steam extraction pipeline of the steam turbine and the TRT intake pipeline of the blast furnace gas residual pressure power generation device, and is used as an emergency shut-off valve; when the system has a crisis condition, it will be installed at 0.3 - Implement emergency valve closing within 0.8 seconds to achieve reliable cut-off of pipelines, effectively preventing steam and condensed water at the tail of the steam turbine from being poured back or cutting off the gas pipeline, which is a mechanical equipment to ensure the safety of the generator set.

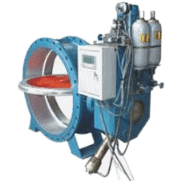

Quick closing hydraulic control butterfly valve consists of main valve, rack and pinion cylinder transmission device, hydraulic system and electrical control system.

The main valve is a triple eccentric metal-sealed butterfly valve, which is equipped with a unique angular eccentric design based on the traditional double eccentric structure, and makes full use of the cam effect to make the sealing pair contact and disengage instantaneously when the valve is opened and closed, eliminating friction and Squeeze card, small wear, high temperature resistance, easy opening and closing, and reliable sealing

The rack and pinion transmission box has a compact structure and is directly connected with the oil cylinder; the tail of the oil cylinder is provided with a buffer device to eliminate the inertial impact during fast closing and prolong the service life of the valve.

Hydraulic system is divided into two categories according to the different power sources of quick closing: spring energy storage quick closing YKD and accumulator energy quick closing YxKD. The normal opening and closing power source of the valve is generally supplied by the oil pump in the hydraulic system. It can also be supplied from the supporting hydraulic station of the steam turbine main engine. The normal opening and closing speed is adjusted and controlled by the flow valve.

The electrical control system is divided into ordinary relay type and PLC intelligent control type according to the main logic element category. The factory matching is generally ordinary relay type. The PLC intelligent control type should be specified when ordering. In addition to conventional control actions such as valve opening, normal valve closing, stop, quick valve closing, etc., a 15% stroke "swimming" function in the fully open state is also set to avoid valve jamming.

The electromagnetic reversing control characteristics of the hydraulic system are generally positive-acting, that is, the solenoid valve has a power-on butterfly valve 7T valve, and the power-off butterfly valve closes the valve; otherwise, it is a reactive type. The conventional matching electromagnetic reversing valve is a positive-acting type , the reaction type should be specified when ordering.

The system power supply is AC380V, and the control power supply can be AC220V, DC220V, DC110V or other power levels.